This article is one of our DS Does Japan series from our recent trip to the land of the rising sun, courtesy of Toyota Australia. Click here for the whole set!

![]()

The team arrived in Nagoya late one evening on the trip and headed back to our hotel to check in and drop our stuff off.

We came across this Jag in the dying light. I’m a huge fan of these.

The next morning dawned bright and shiny.

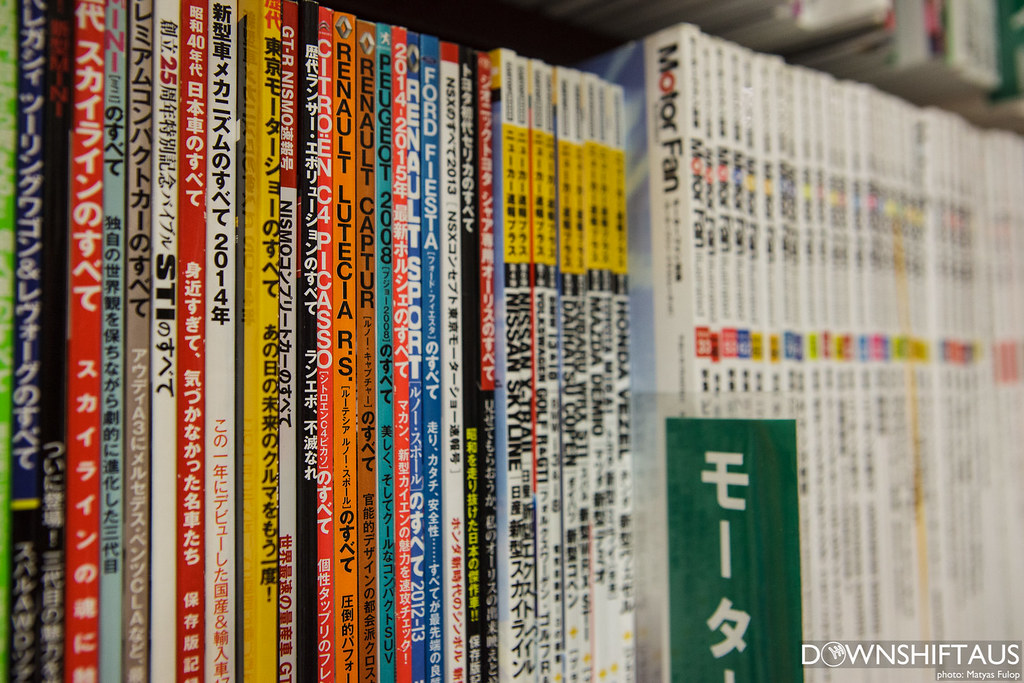

We opted to check out a bookstore, which had an incredible selection of automotive magazines, books and knowledge, with people of all ages and sexes perusing them. Just try and imagine that concept in Australia! I tried to find one for the S2000, but it was like looking for an English needle in a Japanese haystack.

A bit of amazing ramen was the order of the day once again. Despite having eaten it many times on the trip, I didn’t even consider getting sick of it.

But the reason we were in town was to check out Toyota City!

We actually got to go for a several hour tour of the Motomachi Plant, where they produce the Crown, the Mark X and Estima. You’ll see a few examples of these Japan-only cars in the Toyota Megaweb article. We got heaps of really interesting info from the guys there, both about the company generally, as well as about the manufacturing process:

- Stamping: Steel sheets are cut and stamped to form body parts. High precision is achieved through the latest stamping machines and high speed transfer robots.

- Welding: Robots weld about 400 body parts to form a car. The latest welding line can handle multiple models on a single line and produce precisely finished car bodies. We walked across a catwalk above about 10 of these lines, the crazy-looking welding machines like the legs of an upside-down spider, lit by sparks whizzing everywhere and the blue and gold glow of molten and burning metal.

- Painting: After the body is washed, undercoat, intermediate and topcoat are applied to create a high-quality surface.

- Assembly: At this line, engines, wheels and other parts are installed. Fully assembled vehicles are tested and verified in the final inspection, before being shipped. We also saw a bunch of these lines from above. It was fascinating watching people tow tiny trains of parts around the chaotic-looking factory to be fitted to car skeletons. But once the process was explained, it all made sense! Various musical tones and lights indicated everything from whether bolts were correctly tightened, to the overall efficiency rating of the entire line.

Unfortunately taking photos in the factory itself was strictly prohibited, totally understandably. We did ask the question though, were keen to show you the inside of a Toyota factory! Guess it’ll have to be Megafactories documenting it.

Heading back into the lobby, there were various cool things on display, like this race-prep-ready 86.

An i-ROAD

And other hybrid prototypes, TE-S 800 and 555TES MINUTE-S.

The mighty LFA. This one is actually a prototype model, so is not numbered in the 1-500 production release.

This model is signed by chief engineer Haruhiko Tanahashi. There is only one in the 500 production run that is also signed by Haruhiko, and it is actually located in Australia! It was originally in Brisbane, but now resides in Adelaide.

Australia really gets boned in price because of our luxury car tax. Around A$400k in Japan, the price is A$780k new in Australia.

Exploded view.

2011 Gazoo Racing 24hrs of Nurburging race-version

Very cool concept.

New RCF coupe

Sitting next to a special edition resurrected 70-series LandCruiser.

This is one of our last Japan articles.. Sayonara from the team!